CRYOGENIC TESTING

Need a quote or have questions about this test? Reach out, and we’ll get back to you promptly!

Cryogenic and Low temp Testing as per BS 6343/ ISO 28921

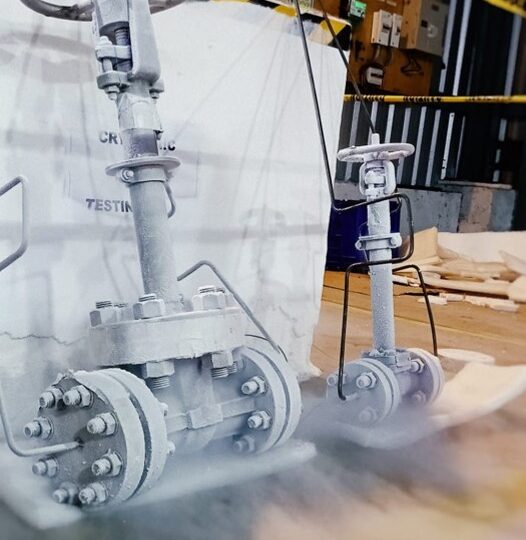

To uphold our commitment to excellence in valve testing and production, we adhere to rigorous cryogenic testing protocols within our advanced testing facility.

With extensive experience in valve testing, our team offers unmatched expertise in conducting tests and resolving challenges for both end-users and manufacturers. This ensures reliable performance under extreme conditions.

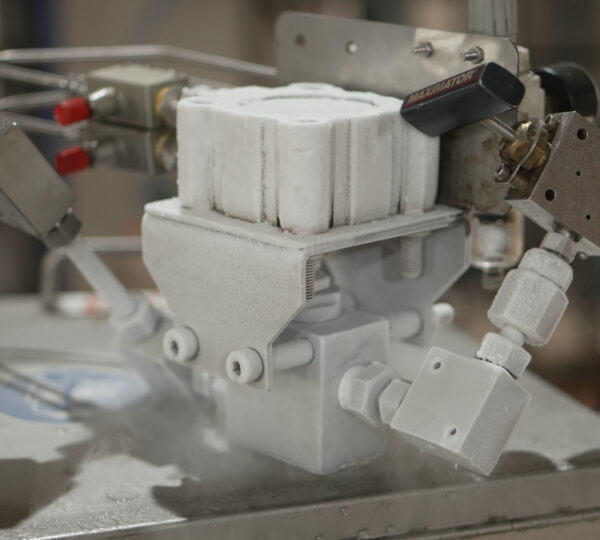

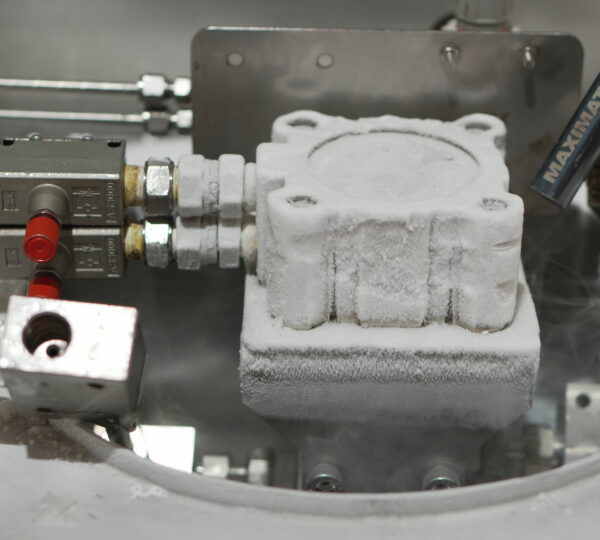

During our cryogenic tests, valves are subjected to precisely controlled temperatures as low as -196°C (the boiling point of liquid nitrogen). We assess critical parameters such as housing and seat leakage, torque values, and operational cycling in low-temperature or cryogenic environments. These tests are performed in compliance with globally recognized standards, including BS 6364 and ISO 28921. Additionally, we can customize testing procedures to meet unique client requirements, ensuring that the results align with the intended application.Examples of applicable standards include ISO 28921-1, ISO 28921-2, BS 6364, and Shell MESC SPE 77/200 and 77/306, ISO 21011. When required, we develop tailored testing protocols to fullfill specific customer needs, guaranteeing valves are fit for purpose.

Our mission is to maintain the highest levels of quality and ensure that test valves reach the actual testing parameters , even under challenging low-temperature and cryogenic conditions.

Examples of applicable standards include ISO 28921-1, ISO 28921-2, BS 6364, and Shell MESC SPE 77/200 and 77/306. When required, we develop tailored testing protocols to fulfill specific customer needs, guaranteeing valves are fit for purpose.

Our mission is to maintain the highest levels of quality and ensure that valves perform reliably, even under challenging low-temperature and cryogenic conditions.